Lake St Clair Amenity Building

- Principal:

- Singleton Council

- Client:

- Singleton Council

- Product/s:

- Custom Byron

- Year:

- 2026

Key Takeaways

- Redesigned and delivered to meet practical completion deadline

- Solar hot water with four roof panels cuts operating costs for 6 shower facilities

- Hot-dip galvanised steel and Colorbond Ultra roofing handle lakeside corrosion

- Non-slip tiles over fibre cement prevent odour absorption in high-traffic shower areas

Lake St Clair sits in NSW's Hunter region located right by the water, and is frequented for boating, fishing, sailing and water-skiing for the entire Hunter region.

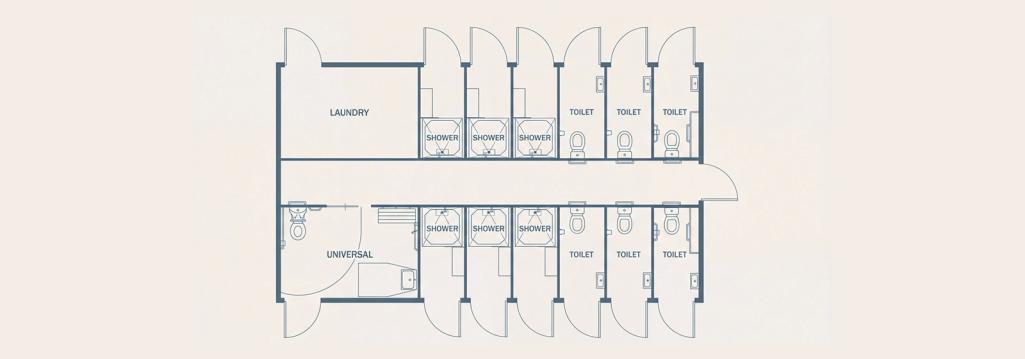

To assist Singleton, we designed and installed a low-maintenance, durable alternative under a tight deadline. The building features 6 showers, 7 toilet rooms, laundry facilities, and hot water powered by solar energy.

The amenity building was installed tiles on-site over compressed fibre cement sheeting.

How does the amenity building resist corrosion?

- Frame: hot-dip galvanised steel welded after fabrication, creating continuous moisture protection.

- Roofing: Colorbond Ultra handles high-humidity environments.

- Door hardware and fixtures: marine-grade stainless steel.

- Ventilation Louvres: Powder coated aluminium to resist weathering and allow for natural ventilation

Why use tiles in toilet building interiors?

- Non-slip tiles over compressed fibre cement create non-porous surfaces that don't absorb odours, critical for buildings in coastal or lakeside locations under constant use.

- Unsealed concrete absorbs odours and moisture. Tiles end up staying cleaner with less work and chemicals, reducing maintenance costs. In this case, we supplied the fibre cement substrate.

How was the amenity building delivered to deadline?

Off-site manufacturing continued whilst site preparation progressed. The installers received our pre-fabricated panel system for quick assembly, which allowed for meeting the practical completion deadline.

- Compressed fibre cement sheeting: Moisture-resistant substrate for tile installation

- Powdercoated aluminium louvres: Perforated elements above doors, robust and allowing for natural flow of ventilation

- Marine-grade stainless steel fixtures and fittings: All fixtures and fittings corrosion proof for proximity to water

- Slimline water tanks: captures roof rainwater for reliable washdowns, cleaning, and maintenance

Want to build something similar? Get the costs & specs

Get a full breakdown of costs, specs, and materials – just fill in your details, and we’ll be in touch ASAP.